Why Fertilizer Manufacturers in Kolkata Need ERP: Reducing Waste & Boosting Productivity

In today’s competitive agrochemical market, fertilizer manufacturers in Kolkata face growing challenges — from fluctuating raw material costs and waste management to demand forecasting and compliance tracking. To stay competitive, companies are turning toward ERP for fertilizer manufacturing — a single, unified system that automates production, optimizes resources, and improves overall efficiency.

Implementing a robust ERP software in Kolkata is no longer a luxury — it’s a necessity for sustainable growth and profit. Let’s explore how an ERP system can help fertilizer manufacturers reduce waste, boost productivity, and streamline operations through manufacturing process automation and inventory ERP solutions in Kolkata.

Understanding the Challenges in Fertilizer Manufacturing

Before diving into solutions, let’s look at the major roadblocks that fertilizer manufacturers typically face:

- Complex production processes: Multiple stages from blending, drying, and packaging often lead to inefficiencies and inconsistencies.

- Excessive waste: Overproduction, poor raw material tracking, and mismanagement increase operational costs.

- Inventory mismatches: Difficulty in tracking stock levels across warehouses can cause shortages or overstocking.

- Compliance requirements: Fertilizer and chemical industries face strict environmental and quality regulations.

- Manual data handling: Paper-based or spreadsheet systems slow down communication and decision-making.

These pain points highlight why adopting ERP for fertilizer manufacturing is vital for any company aiming to maintain product quality and operational transparency.

How ERP Software Transforms Fertilizer Manufacturing

An ERP software in Kolkata provides a complete digital backbone for fertilizer production companies. It integrates every function — from procurement and inventory to quality control and dispatch — into one centralized system. Here’s how it drives transformation:

1. Smart Resource Planning and Procurement

ERP systems automate material requirement planning, helping manufacturers purchase raw materials based on demand forecasts. This ensures timely procurement, reduces stock-outs, and avoids overbuying.

2. Streamlined Production Management

With real-time visibility into production lines, ERP allows better monitoring of blending, granulation, and packaging. Managers can track batch performance, identify bottlenecks, and improve efficiency using detailed data insights.

3. Waste Reduction and Cost Control

Waste in fertilizer production often stems from inaccurate demand estimation, poor quality control, or untracked by-products. ERP helps by providing traceability from raw materials to finished goods. Manufacturers can monitor wastage patterns, improve formulations, and cut down rejections.

4. Efficient Inventory and Warehouse Management

Managing multiple warehouses can be chaotic without automation. An inventory ERP solution in Kolkata gives real-time visibility into stock levels, batch numbers, and expiry dates. This ensures that older batches are dispatched first, preventing product spoilage.

Pro Tip: With Odoo ERP’s automated inventory alerts, manufacturers can maintain the right balance between supply and demand — reducing waste while maintaining smooth operations.

5. Quality Control and Compliance

Fertilizer industries must meet strict chemical composition and environmental standards. ERP systems streamline compliance by recording every stage of the production process. Automated alerts ensure that all batches meet safety and quality norms before dispatch.

Boosting Productivity with Manufacturing Process Automation

Automation is the backbone of modern manufacturing. By integrating manufacturing process automation, ERP systems eliminate repetitive manual tasks — such as data entry, production tracking, and report generation — freeing up manpower for more strategic activities.

Key Productivity Gains Include:

- Faster production cycles: Automated scheduling minimizes downtime.

- Accurate reporting: Real-time dashboards help managers make quick, data-driven decisions.

- Improved collaboration: Departments from production to sales stay connected through a shared database.

With the right ERP software in Kolkata, fertilizer manufacturers can witness productivity jumps of up to 30–40%, depending on their current operational maturity.

Real-Time Analytics for Smarter Decisions

In the age of data, decision-making should be driven by insights, not guesswork. ERP software offers detailed reports on production efficiency, cost per batch, material utilization, and wastage.

With these insights, managers can identify trends, make strategic adjustments, and optimize production performance.

For example, a fertilizer plant in Kolkata can use ERP analytics to:

- Forecast seasonal fertilizer demand

- Track raw material cost trends

- Optimize transportation routes

- Reduce idle machine hours

Integrating ERP for End-to-End Business Efficiency

An ERP for fertilizer manufacturing does more than just production automation — it connects all departments across the enterprise. From HR and finance to sales and logistics, everything works in harmony.

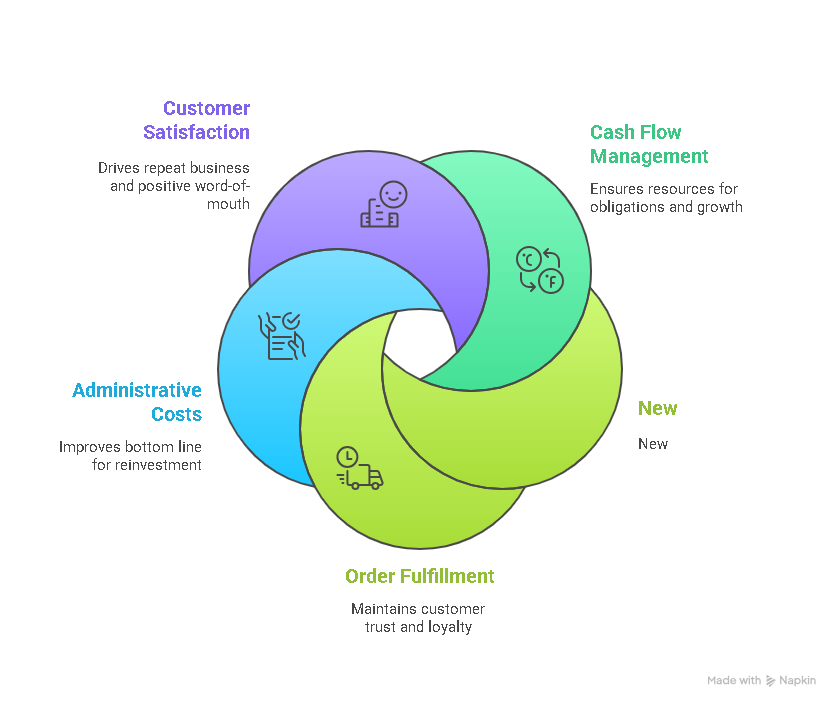

When data flows seamlessly between departments, it results in:

- Better cash flow management

- Timely order fulfillment

- Lower administrative costs

- Enhanced customer satisfaction

Whether you run a small manufacturing unit or a large-scale plant in Kolkata, ERP ensures every resource is utilized optimally.

Why Choose Odoo ERP for Fertilizer Manufacturing in Kolkata

Odoo ERP stands out for its flexibility, scalability, and modular design — perfectly suited for fertilizer manufacturers in Kolkata. Its advanced features for inventory, production, accounting, and CRM make it one of the best ERP software solutions in Kolkata.

Benefits of Odoo ERP for Fertilizer Manufacturers:

- Modular system for production, inventory, and finance

- Real-time material traceability and batch tracking

- Easy customization for fertilizer formulations

- Integration with IoT for machine-level monitoring

- Detailed analytics for cost and performance optimization

Case Study: How ERP Reduced Waste by 25%

A mid-sized fertilizer manufacturer in West Bengal recently implemented Odoo ERP through Primacy Infotech Pvt. Ltd., an Odoo Silver Partner in Kolkata.

Within six months, they achieved:

- 25% reduction in raw material waste

- 40% improvement in production speed

- 100% traceability across supply chains

By automating workflows and integrating data, the manufacturer not only cut costs but also improved sustainability metrics — a major step toward green manufacturing.

How Primacy Infotech Helps You Implement ERP Successfully

As a certified Odoo Silver Partner in Kolkata, Primacy Infotech Pvt. Ltd. specializes in implementing ERP systems tailored for fertilizer and agrochemical industries.

Our team understands the local manufacturing ecosystem and offers complete support — from process mapping to training and post-implementation maintenance.

Our ERP Implementation Includes:

- Custom module development for fertilizer production

- Inventory and batch control setup

- Quality assurance integration

- Employee training and technical support

With deep domain expertise, Primacy ensures your business gets measurable outcomes — reduced waste, improved efficiency, and higher profits.

Final Thoughts: The Future of Fertilizer Manufacturing Is Digital

The fertilizer industry in Kolkata is evolving rapidly — and only those embracing technology will thrive. Implementing an ERP for fertilizer manufacturing is the smartest way to minimize waste, automate operations, and maximize productivity.

If you’re ready to take your fertilizer business to the next level, it’s time to move beyond manual spreadsheets and legacy systems. Choose Primacy Infotech Pvt. Ltd., your trusted Odoo Silver Partner in Kolkata, to design a tailored ERP solution that accelerates your growth.

🚀 Get Started Today!

👉 Schedule a free consultation with Primacy Infotech Pvt. Ltd. — your local Odoo Silver Partner in Kolkata.